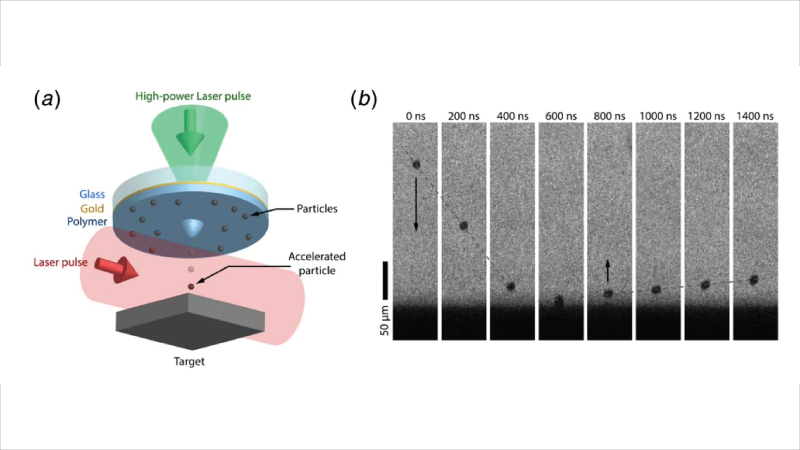

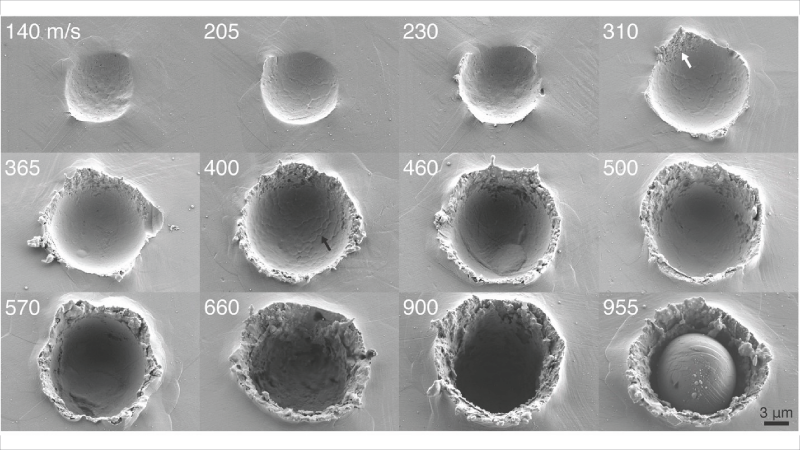

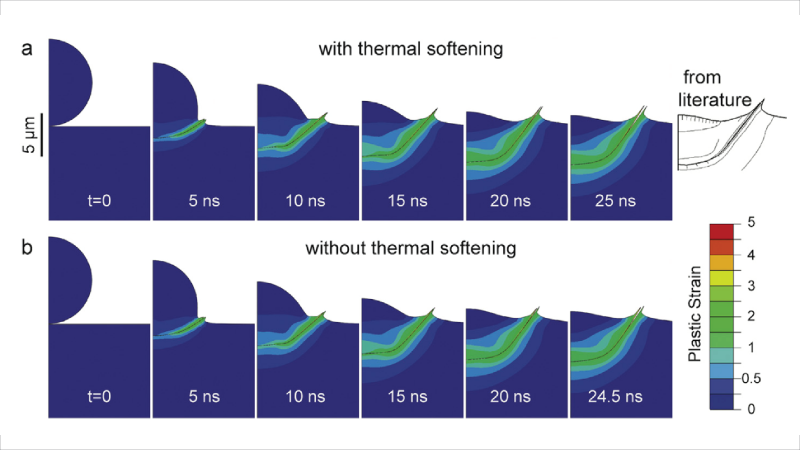

A wide range of interesting phenomena can occur when metallic particles impact metal surfaces at supersonic speeds, including adhesion, melting, cratering, erosion, and hydrodynamic shock-induced jetting. The Schuh group is systematically investigating high-speed microparticle impacts using a new real-time observation method that allows for direct nanosecond scale observation of the moment of impact, as well as finite-element modelling. Single particle impact experiments are directly relevant to additive manufacturing techniques such as cold spray, where powder is accelerated with a gas jet and rapid plastic deformation enables adhesion of the powder to a substrate upon impact. These experiments are also useful in studying impact-induced erosion, where at even higher velocities, rather than adhering to the substrate, impacting particles will cause ejection and loss of substrate material.

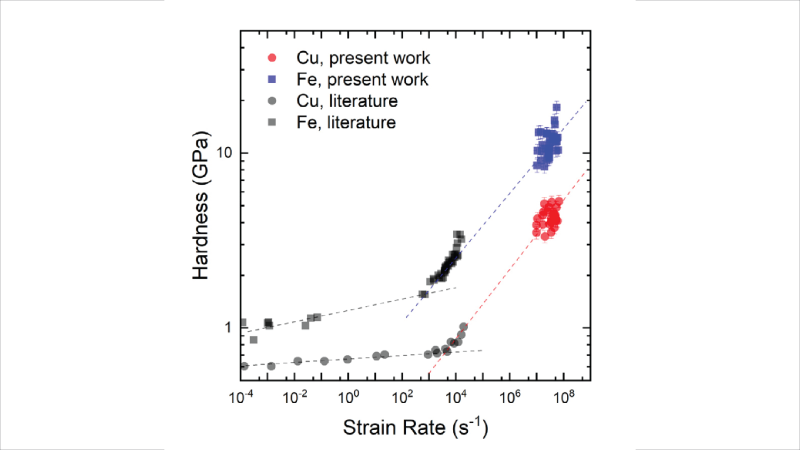

In addition to an array of engineering applications, microparticle impact tests are useful for fundamental studies of ultra-high-strain-rate mechanics. These experiments allow for precise measurement of the kinetic energy dissipated by plasticity upon impact, as well as the volume of contact impressions created by impacts. This information can be combined to calculate hardness and dynamic yield strength measurements of metals at strain rates on the order of 10^6 to 10^9 s^-1, rates far greater than can be obtained by traditional indentation hardness tests.

Microparticle Impact Testing at High Precision, Higher Temperatures, and with Lithographically Patterned Projectiles

Our new publication introduces a new launch pad architecture for laser induced particle impact testing (LIPIT) that brings some exciting new capabilities to the method. Read more about it in Small Methods.

New publication on tin and zinc microparticle impacts above the critical adhesion velocity

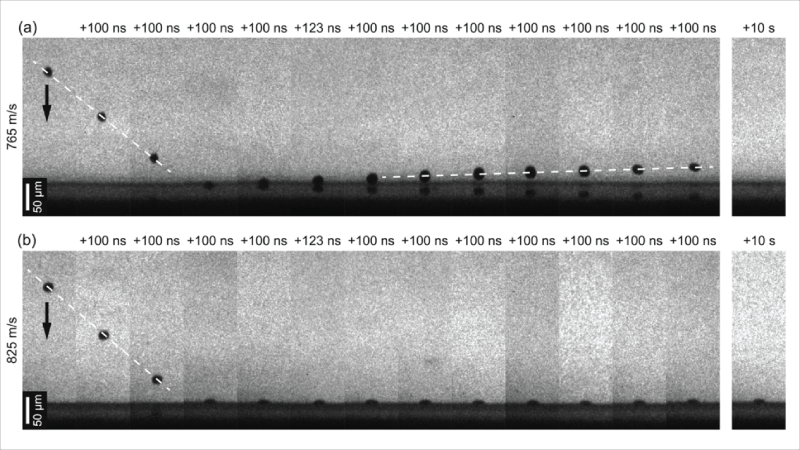

Above the velocity that particles adhere, interesting phenomena can arise, including jetting, melting, fragmentation, and hydrodynamic penetration.

Check out our new paper on tin and zinc microparticle impacts above the critical adhesion velocity on Surface and Coating Technology!

Oxide delamination during high-velocity microparticle impacts

Understanding how oxide layers form and delaminate upon microparticle impacts is important for optimizing cold spray processes. Check out our new publication on oxide layer delamination on Applied Surface Science!